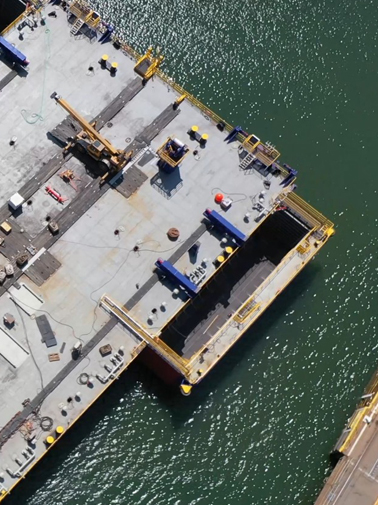

Ship Design & Conversion

Detailed engineering

During the Detailed engineering phase, we translate the developed ship design into a fully integrated, production-ready engineering package. This includes high-detail 3D modeling of the hull structure, systems, and outfitting, with all necessary data extracted to support manufacturing, assembly, and installation. Every element is modeled with precision, taking into account weld details, material specifications, access provisions, and integration with equipment and systems.

We deliver workshop and construction drawings, isometrics, installation guides, and production documentation tailored to the specific standards and methods of the selected yard. Systems such as piping, HVAC, and cable trays are fully routed and supported in coordination with structural and outfitting elements. Material lists and BOMs are optimized for procurement and aligned with the build strategy. Class requirements are embedded into the design, and all outputs support digital workflows such as clash checks, revision control, and integration with PLM or ERP systems.

Throughout the process, we maintain close collaboration with the shipyard, suppliers, and classification societies to ensure alignment across disciplines and prevent issues before they arise. By focusing on buildability, clarity, and technical consistency, Saltwater’s detailed engineering forms a solid foundation for an efficient, low-risk construction phase.