Our field of expertise

Hull of a job

Saltwater was contracted to deliver the detailed engineering for the repair works of a container vessel.

A 400 Ton Steel, 40 days repair challenge

Saltwater was brought in to deliver the detailed engineering for the repair works of the 300m container vessel. At the time Saltwater became involved, the time pressure on the project had changed. Initially, the damaged area of the vessel seemed not too complex. Saltwater first modelled the aftship in FEM software and after modeled prefab steel sections to repair the damage. When the vessel arrived and after assessing the damage, the full nature of the structural damage became apparent. The damage stretched from the bilge to the hatch coaming. To repair this, a substantial part of a structural bulkhead had to be replaced. The structural repairs that had to be done to frames and the greater part of one of the bulkheads introduced a new challenge.

Next level

The vessel would have to be docked for the full duration of the repair, where the original plan was to part perform the necessary repair work at quayside. The actual repair job grew to a hefty 400 tons of steel. To repair the damage within the 40-day tight time window, 12-tons of steel per day would be needed to complete the job. Cutting, forming and prefab engineering preparations hit a brand new level, adding to the job’s complexity.

Remodeling

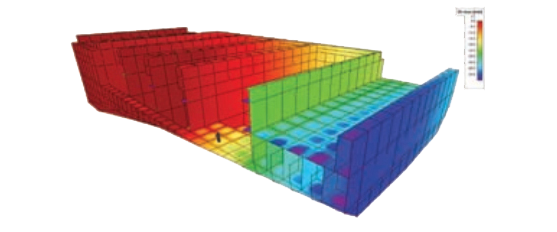

Saltwater not only engineered and modeled the steel plate sections, but also had to remodel the vessel to such a detail, that by means of finite element modeling and analysis, the effect of the initial docking and blocking setup of the vessel could be examined. Saltwater remodeled the vessel in 3D to guarantee a perfect fit of all structural members and hull plates that had to be replaced. The length that had to be remodeled was over 100m of the vessel. This meant from the forward engine room bulkhead to the stern. While only being provided with 2D general construction drawings by the builder of the vessel, this was certainly not an easy task.

The vessels shoring had to prevent any deformation by forces that would interfere with the patterning of frames and plates to restore the vessel to its former glory. Due to our flexible and professional approach, the repair could be completed within the stipulated 40 day deadline. A truly remarkable achievement.

Specific project data

Project information

Challenges:

- Extreme short timeframe

- Generation of as-built information

Deliverables:

- Detailed engineering package