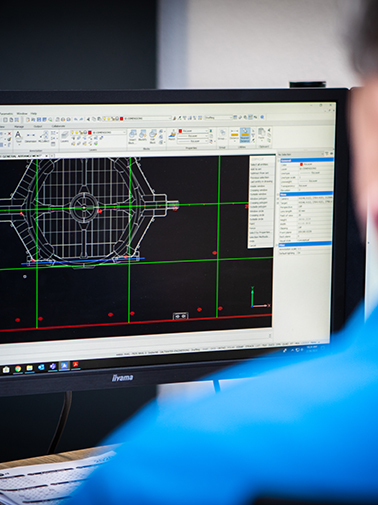

Our field of expertise

On-site Services

Saltwater offers comprehensive on-site services, ensuring meticulous attention to various maritime needs. Weight and stability surveys are conducted with precision, ensuring vessels adhere to safety standards and optimal performance. These surveys evaluate the distribution of weight, ensuring stability in various conditions, crucial for safe navigation. Specialist surveys provided by Saltwater encompass diverse aspects such as structural integrity, environmental compliance, and technical assessments. Our expertise extends to niche areas, guaranteeing thorough evaluations tailored to specific requirements, fostering confidence in vessel operations.

On-site engineering support from Saltwater is invaluable, providing immediate solutions to technical challenges. Our skilled engineers offer practical insights, troubleshooting issues efficiently to minimize downtime and optimize performance. Whether it’s routine maintenance or complex repairs, our on-site presence ensures swift resolution, enhancing operational efficiency and reducing risks. In essence, Saltwater’s on-site services encompass weight and stability surveys, specialist evaluations, and engineering support, reflecting our commitment to excellence and safety in maritime operations.