Our field of expertise

Maritime Engineering

Saltwater is your trusted partner for seamless deck integration, mobilization, transport engineering, software utilization, and tooling design in maritime operations. Our expertise ensures stress-free integration of structural components and equipment like bulwarks and crane pedestals, exceeding client expectations with customer-centered strategies. We specialize in temporary structural changes for mobilization, offering enhanced equipment performance and precise sea fastening calculations.

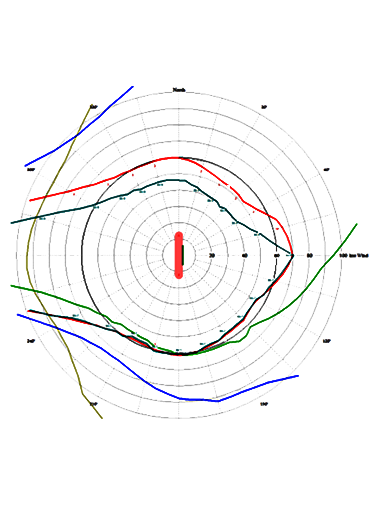

In transport engineering, Saltwater conducts wave load analyses and specializes in rigging designs for heavy lifts. Utilizing advanced software, they tackle ship design challenges effectively, consulting clients for preferred solutions. Our tooling and lifting appliances prioritize safety and efficiency, tailored to marine industry needs for durability and functionality. Saltwater’s solutions are optimized for offshore environments, ensuring seamless integration into various operations with exceptional quality.