Our field of expertise

Outrigger frame

Saltwater was contracted by Jumbo shipping to complete the design and strength calculations for an outrigger frame for the purpose of lifting the tower.

Ocean transport

Jumbo Shipping was contracted by IMECA for the ocean transport of two pipe-lay towers from Gdynia, Poland, to La Rochelle, France. Once all assembly work had been completed in La Rochelle, the fully assembled towers were shipped to Okpo, South Korea. Since only one tower was transported at a time, a total of four shipments were scheduled to complete the project.

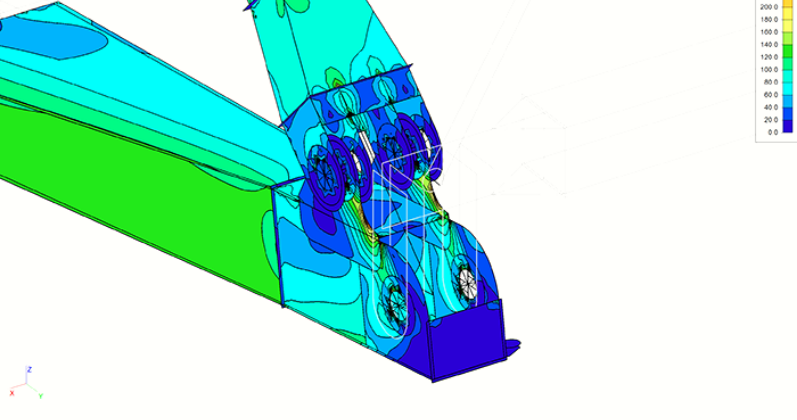

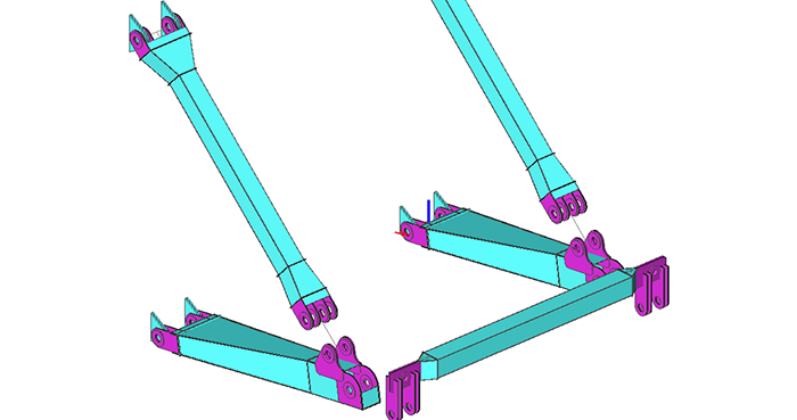

In Okpo, the towers were further prepared for installation on a pipe-lay vessel. As part of Jumbo’s scope, the design of the outrigger construction was required. Saltwater was contracted by Jumbo Shipping to develop the design and perform strength calculations for an outrigger frame to facilitate the lifting of the towers.

The transport requires an extension of the towers, so the vessel’s cranes can reach the lifting points. The center of gravity of the tower is too high to be lifted by the baseframe, hence the lifting points need to be raised. As both towers will be shipped in different transports, the lifting tools require to be re-usable and demountable. The outrigger structure that was developed for the lifting is connected to the tower by means of pins through the structural pad-eyes that are present for fixing the tower to its new mothership. The outrigger structure is built of S355 and the connection points consist of S690 steel quality. The pins are made of 42CrMo4 steel. The cross-braces include threaded rods to be able to adjust the length of the braces after installation of the main lifting structure to improve ease of installation.

Specific project data

Project information

Scope of work:

- Design and strength calculations

Weight:

- Completed tower approx. 1800 tons

- Outriggers are approx. 50 tons each