Afmeer analyses

Saltwater heeft geassisteerd bij de verificatie van de afmeerindeling voor meerdere transportschepen.

Offshore floating wind farming calls for innovations that support the installation of the wind turbines. Quicker, simpler and safer installation methods win ground in the wind energy industry.

Maak kennis met

In the offshore floating wind industry, opportunities to reduce costs are substantial. Much is to be gained from innovations that provide quicker, simpler and cost-efficient supporting equipment. Clever engineering have a direct effect on offshore cycle times and thus considerably increase revenue of offshore floating wind projects. At the same time, focus must remain on health and safety considerations as the importance of energy from floating offshore wind appears to be long term.

Typical steps in the process of outbound operations involve:

Obviously, outbound operations have a high risk of weather downtime: the farther away from shore, the higher the risk. Low workability increases cost levels which automatically calls for smart solutions.

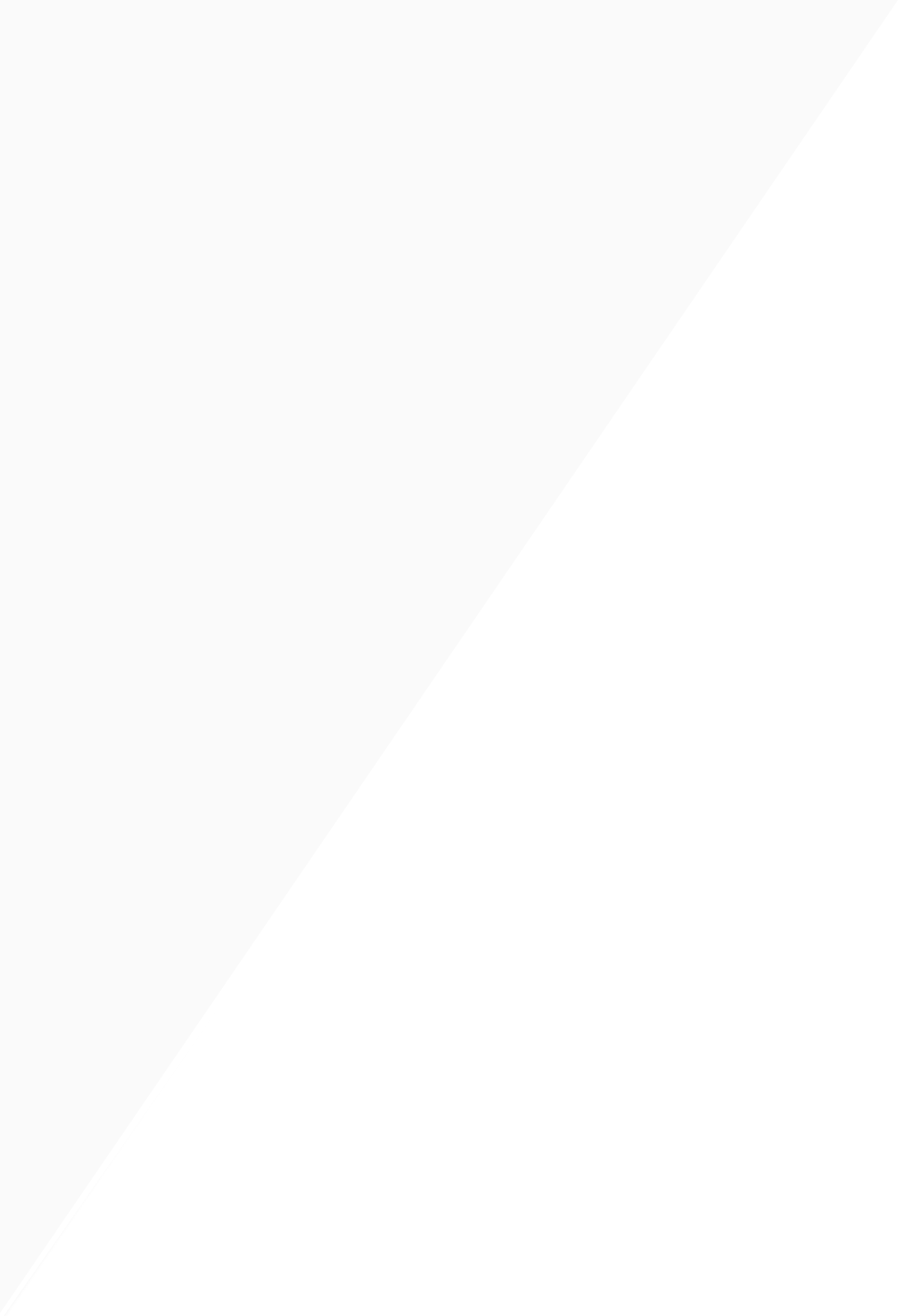

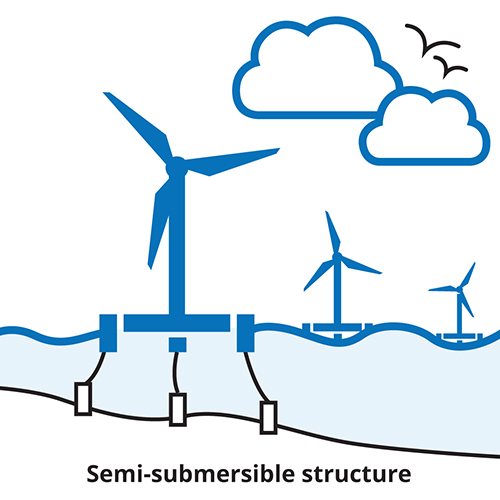

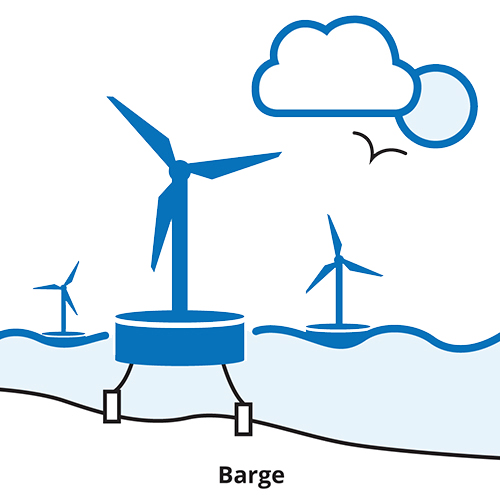

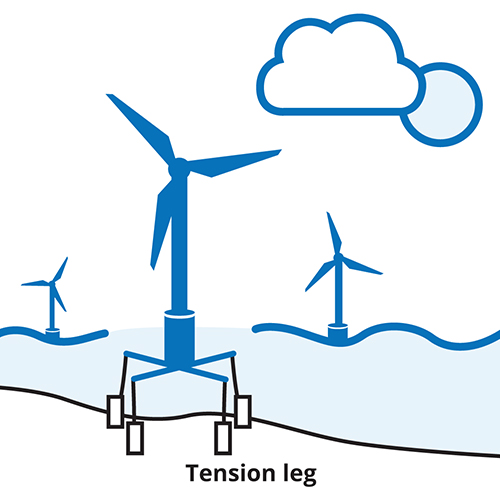

In the floating wind technology various types of substructures exist. Although their goal is common, distinctions can be made. This text sheds light on some of differences.

The semi-submersible substructure has three or four buoyant columns and surrounding floating elements that are interconnected by means of pontoons or trusses. Stability is provided by ballast material. Semi-submersibles are suitable for water depths of > 40m and have various design options which makes them applicable in varied configurations. Two pre-commercial pilots have already proved successful.

Barge substructures are smaller than submersibles. They are suitable for water depths greater than 40 m and have a single hull that pierces the waterline. Stability derives from their large surface area in the water. As this obviously makes them more susceptible to waves, various designs provide alternatives to compensate for this.

Suitable for water depths above 100 m, spar substructures are tall cylinders. Dense ballast in their lower part brings their centre of gravity below their centre of buoyancy which makes them self-righting. Their particularly large draft makes them less susceptible to heavy weather conditions on the one hand, but limits site locations due to their difficult towing conditions.

Tension leg platforms, or TLPs, are floating substructures that are used in the oil and gas industry. They are suitable for water depths above 80 m and have design variables in material and construction.

Saltwater presents Blue Sky, a Service operation vessel, specially designed for the emerging offshore wind market.

We zetten ons in om maritieme oplossingen te ontwerpen en te ontwikkelen die de impact op het milieu verminderen en een lage CO2-voetafdruk ondersteunen. Om innovatieve en efficiënte engineeringdiensten te leveren die voldoen aan de behoeften van onze klanten en om voorop te lopen bij het leveren van duurzame oplossingen voor de maritieme industrie. Dankzij onze kracht en strategische keuze om ons te richten op zowel de verbouwings- als de nieuwbouwmarkt kunnen we onze klanten het beste van twee werelden bieden.

We verwachten een enorme groei in de sector van wind- en zonne-energie, aquacultuur in open oceanen en andere soortgelijke duurzame sectoren van de industrie waar gespecialiseerde middelen zoals onderzoeks-, constructie- en onderhoudsschepen nodig zijn. Dit kan allemaal worden toegepast op de bestaande wereldwijde scheepsvloot door ombouw/refit of speciale nieuwbouw.

Marktvooruitzichten

De markt ziet er veelbelovend uit, met voortdurende technologische vooruitgang en een groeiende inzet voor duurzame energieoplossingen. Lees meer over de vooruitzichten van Saltwater voor de verschillende beïnvloede marktsegmenten.

De expertise van Saltwater in de praktijk

Saltwater heeft geassisteerd bij de verificatie van de afmeerindeling voor meerdere transportschepen.